Building blocks for Limitless Innovation

Get to know Our Technology

Single piece 3D printed semi cryogenic engine

Fully mobile launchpad

Clusterable configuration

Fully inhouse designed autopilot

Inhouse avionics

Inhouse propulsion components

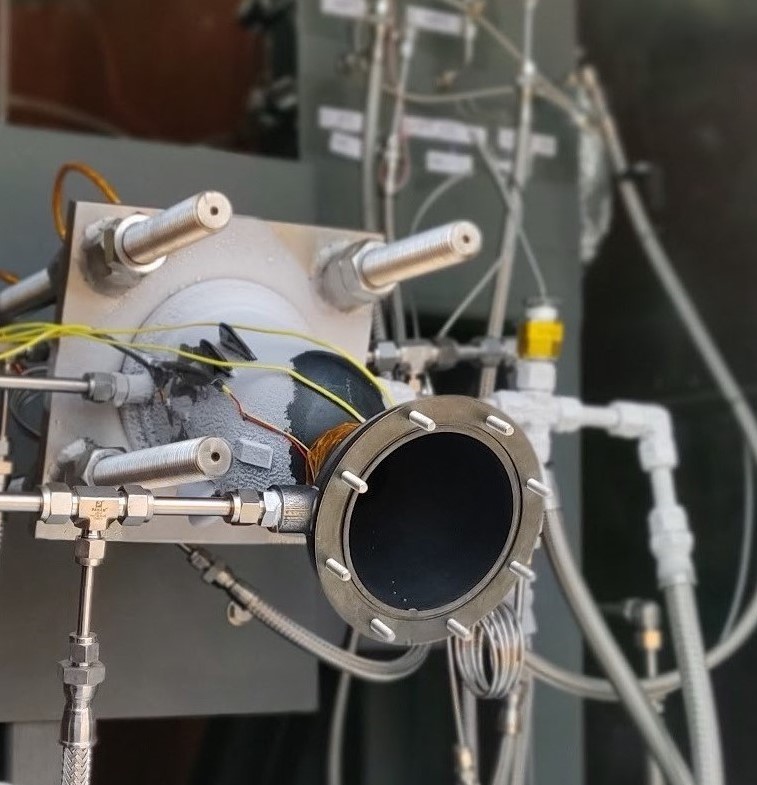

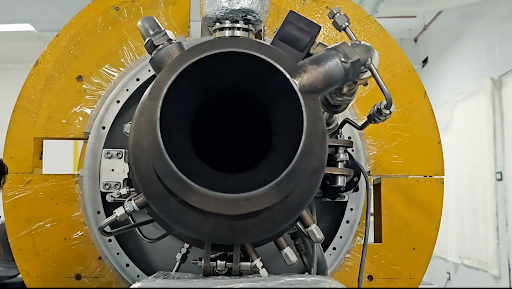

Single piece 3D printed semi cryogenic engine

The future, printed today

Single piece 3D printed semi cryogenic engine.

Traditional rocket engines take months to build and need thousands of parts assembled by welding and brazing. Our semi-cryogenic engines, Agnilet and Agnite, are 3D-printed in one piece with no separate parts or assembly needed. Designed and printed in-house using inconel, they include everything from the injector to cooling channels. After printing, we perform CT scans, heat treatment, grinding, and cleaning to make them ready for flight.

Fully mobile launchpad.

Your launch, your location

Fully mobile launchpad

Cost isn't just about dollars per kg - it's about optimising launch latitude. By choosing the right latitude, we can reduce the launch costs by up to 30%. To meet this need, we developed the concept of mobile launchpad. Its designed to be transported in modular pieces, using a plug-and-play approach that allows for quick and easy assembly at the chosen site. Every component is carefully chosen to ensure safe and hazard-free transportation.

Clusterable configuration

Built to scale, designed to fit.

Clusterable configuration

Lighter payloads don't often require as many engines as heavier ones. That's why the clusterable configuration allows the number of engines to be selected based on the specific mission requirements. At the design stage, the vehicle is built in a modular way, with the autopilot designed to maneuver varying configurations. Both the hardware and software systems are built to accomodate the integration or removal of engines.

Fully inhouse designed autopilot

One autopilot, many configurations

Fully inhouse designed autopilot

As the vehicle adapts to carry lighter payloads, the software also needs to adjust to match these changes. Each mission can require a different setup, so both the hardware and software must be flexible. Our in-house autopilot works with any vehicle configuration and supports the clusterable design. It uses algorithms that run on low-cost sensors, helping reduce the overall cost.

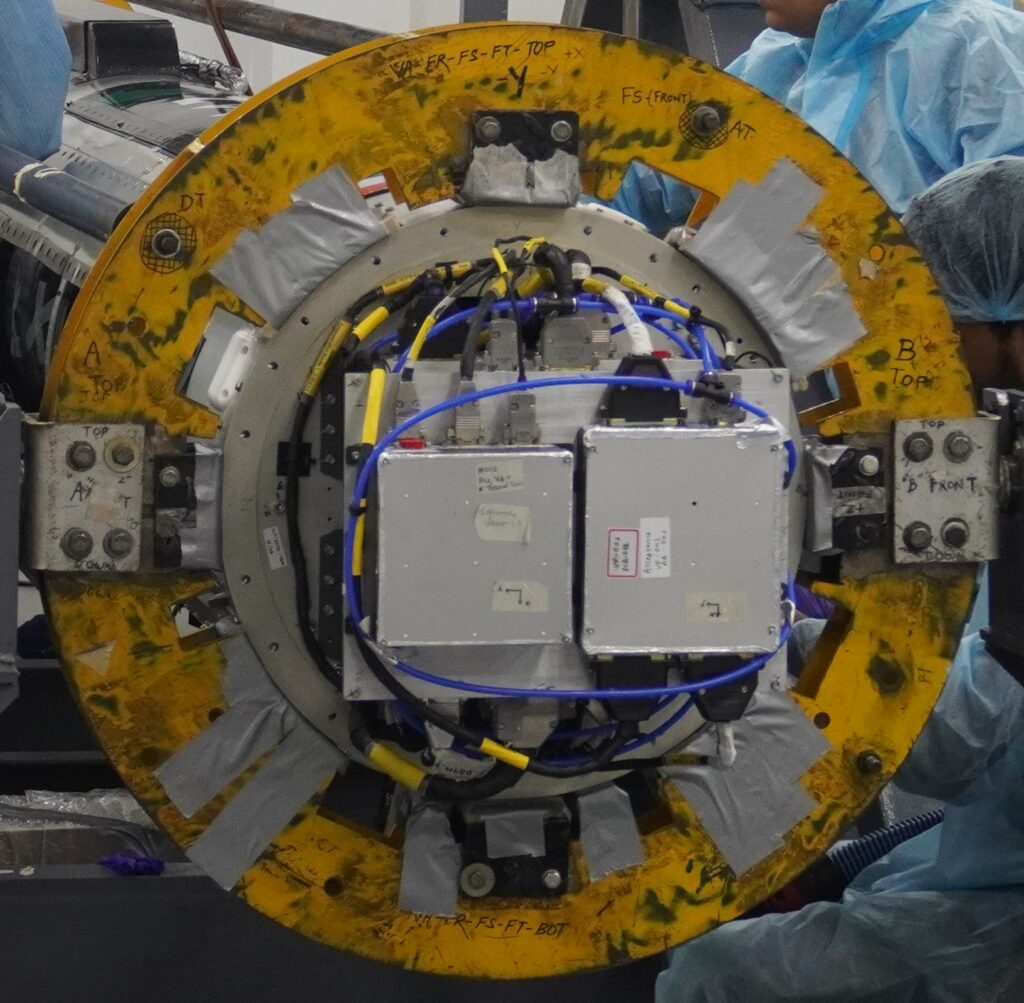

Inhouse avionics

Flight Control Refined

Inhouse avionics

It's not just the engines — often entire systems need to be added or removed depending on the mission. To support this, we built an avionics architecture that follows a plug-and-play approach, where parts of the rocket can be swapped without affecting the rest of the system. Unlike traditional rockets that work as one fixed unit, our in-house avionics treats engines and other systems like plug-in modules. This flexible setup makes it easier to customise the vehicle for different missions.

Inhouse propulsion components

Every detail custom-built for your mission

Inhouse propulsion components

Generic, off-the-shelf propulsion components often fail to meet the performance and integration requirements for customised launch vehicles. That's why we design and manufacture our propulsion components in-house. Injectors and combustion chambers are engineered for optimal flow characteristics, with every element fine-tuned to match your mission profile.